TUSKROBOTS

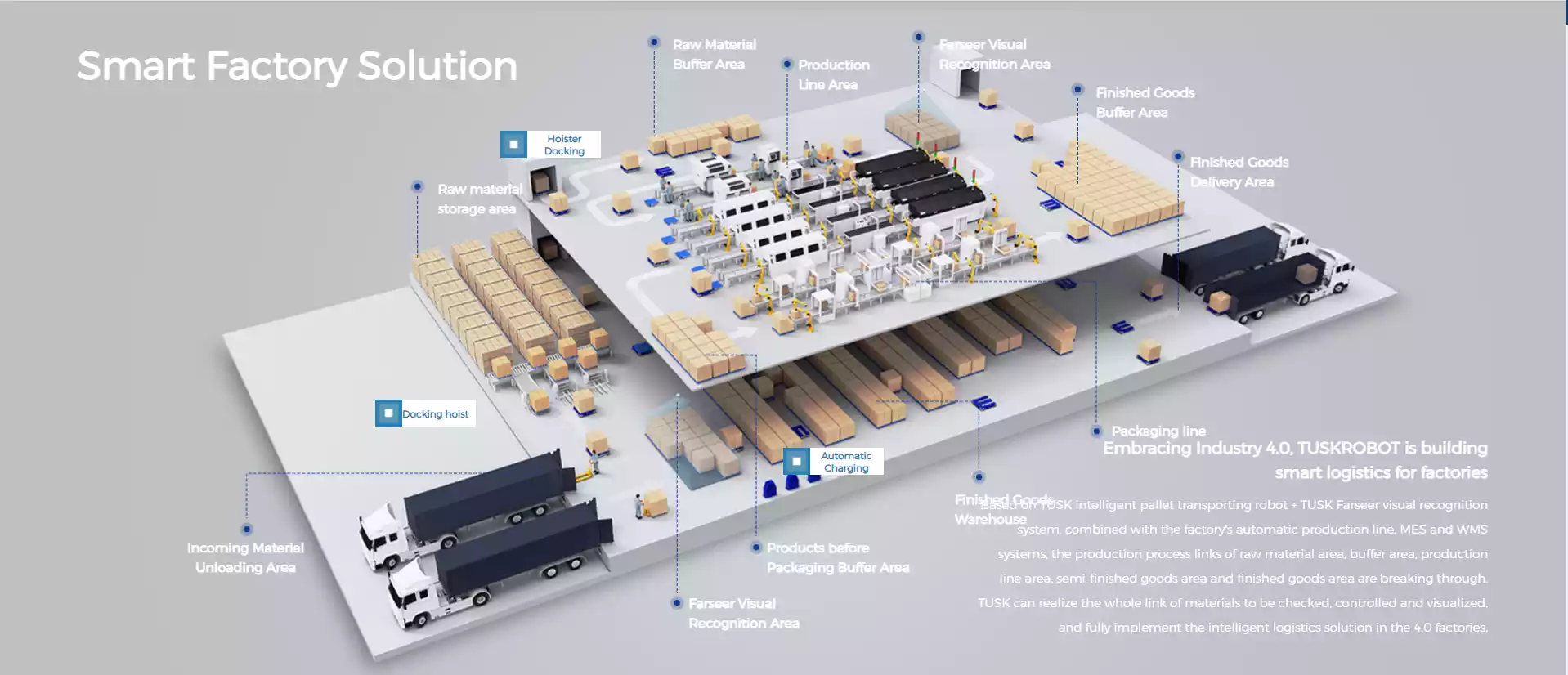

TuskRobots is a high-tech company specializing in pallet handling robots for smart manufacturing and logistics. TuskRobots’ Autonomous Pallet-Handling Robots (APR) stand out by picking pallets directly from the warehouse floor without the need for shelves or racks, unlike other AMR robots. This innovation reduces clutter and manufacturing costs for shelves or racks.

Through its official partner in Vietnam, T&C Industrial Distribution JSC, TuskRobots provides pallet and goods transportation solutions to enhance operational efficiency and increase business value in smart manufacturing plants and the logistics sector.

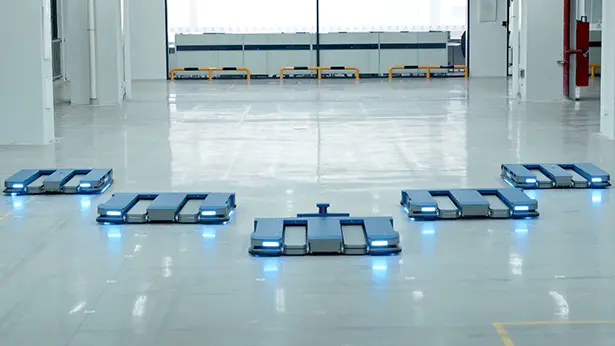

APR Pallet Handling Robots

TuskRobots’ APR robots utilize integrated navigation technology compatible with QR Code and SLAM, the two most popular navigation technologies today. This flexibility allows APRs to switch without the sense and adapt to the needs of multiple sites. In narrow aisles requiring high precision, APRs use QR Code mode. In wider spaces, they switch to SLAM mode for more flexible movement and quicker obstacle avoidance. Featuring a unified interface and TuskRobots’ central control system, Lothar, these robots provide comprehensive pallet handling and distribution solutions.

TuskRobots - Autonomous Pallet Handling Robots (APR)

What are Autonomous Pallet-Handling Robots (APR)?

APRs by TuskRobots are designed for transporting pallet goods in smart factories and warehouses. Equipped with sensors, cameras, and automatic navigation systems, these APRs navigate designated routes, automatically avoid obstacles, and safely transport goods.

TuskRobots - APR Applications in Logistics

- Increased Efficiency: Designed to quickly move heavy pallet loads, APRs speed up operations and reduce the time for pallet transfers.

- Improved Accuracy: Advanced sensors and cameras enable APRs to handle pallets precisely, reducing damage and ensuring accurate order fulfillment.

- Labor Cost Reduction: APRs can operate continuously 24/7, reducing labor costs and increasing productivity by minimizing downtime for breaks, shift changes, and other human activities.

- Flexibility: APRs can be programmed to perform various tasks across different routes and areas, easily adapting to changes in production lines and warehouse operations.

- Enhanced Safety: APRs help reduce accidents, product damage, human injuries, and associated compensation costs.

- Real-Time Data: Equipped with sensors, APRs collect real-time operational and environmental data. This data can be effectively used to monitor warehouse activities, identify areas for improvement, and make data-driven decisions to optimize operations.